Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible

The MIGSO-PCUBED Paris team shares a case study of schedule consolidation and integration on a large-scale project.

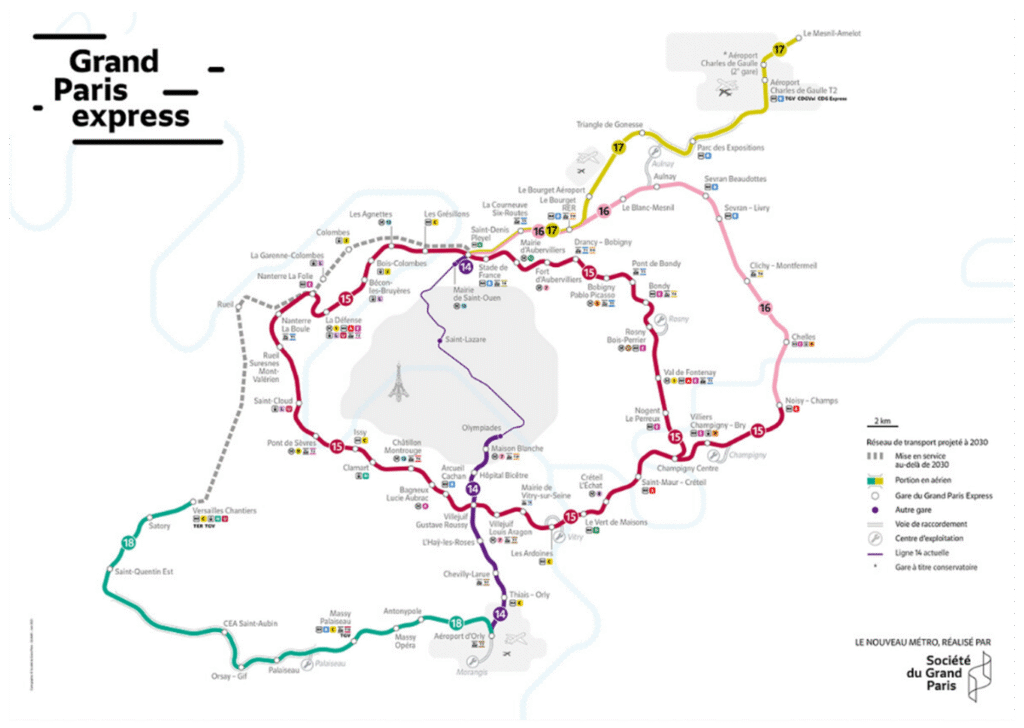

The Grand Paris Express is a project for a public transport network in the Paris region that will enable suburb-to-suburb travel without passing through Paris. It involves the creation of 4 new automatic metro lines, lines 15, 16, 17 and 18, and the extension of an existing line, line 14, between 2024 and 2031.

The Société du Grand Paris, a public establishment created in 2010, is responsible for designing and building the Grand Paris Express transport network, which is currently the largest rail infrastructure project in Europe.

As part of this assignment, our MIGSO-PCUBED team is involved in project controls for the consolidation of existing schedules, and more specifically in making the governing schedules more reliable.

The first step in making governing schedules more reliable was to carry out an audit of existing schedules. There are 7 types of schedules within the company, which can be divided into 2 categories:

Connecting Structures are structures linking the tunnel to the surface. They serve as emergency access for firefighters, evacuation, and ventilation. They are generally placed every 800m.

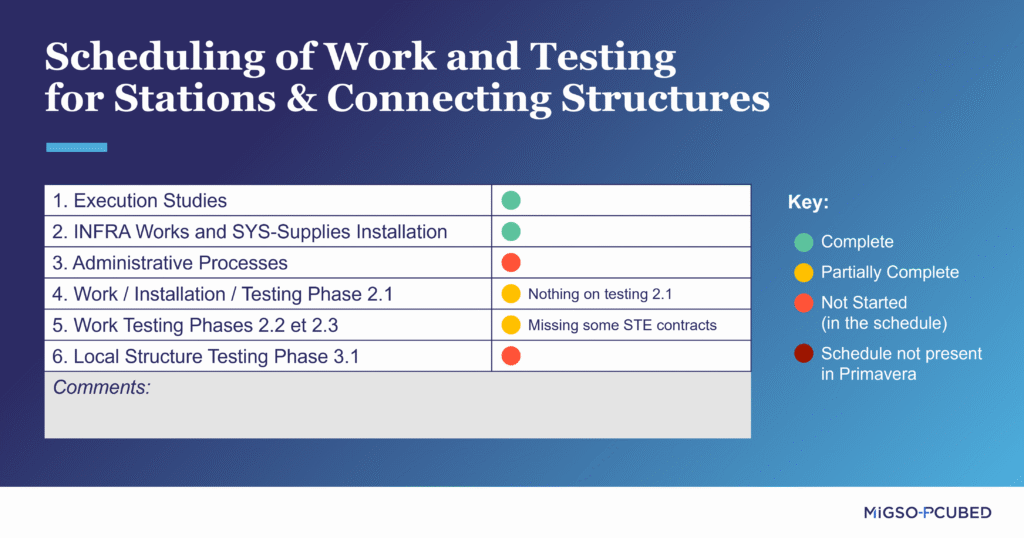

Given the number of schedules to be audited (around 125), we took a sample of these schedules (around 30) and checked their completeness against the baseline, the document outlining all information that must be included.

Below is an example of a line’s station and connecting structure schedules:

As the project progressed, and following discussions with the customer’s scheduling teams, the need arose for a standard sequence on the process of opening a standard Public Access Site.

To create this sequence, the MIGSO-PCUBED team took a flow chart drawn up by the customer’s management and integrated it into the Primavera P6 scheduling tool. Then, to determine typical durations, it used the example of the 1st opening of a current station. The typical sequence thus includes all the stages and documents required from acceptance of the work to the opening of the station.

The initialization of this standard sequence is based on a retro-planning logic, taking the opening date of the station as a reference.

Therefore, we started from the station opening date, to which we attached the tasks in the sequence with the latest scheduled date. There are two main phases to this sequence: “acceptance of work” and “process for compliance and for opening”. The “acceptance of work” phase will be the one that links the standard sequence to the work schedules.

According to the PMI reference system, task sequencing precedes scheduling, which includes the deadlines for each task. By working backwards in the schedule, from the expected station opening date, it is then easy to create the schedule using the sequences and deadlines for each task.

WBS methodology reminder > A sequence of tasks and the resulting schedule are implemented based on the Work Breakdown Structure (WBS).

The ultimate goal is to remove the need to schedule work as late as possible in order to match the actual progress of work at each station. To this end, in the coming months, the standard sequence will be integrated into the governing schedules, so that it can be reworked with all the stakeholders involved to consolidate the “acceptance of work” phase, which will determine the rest of the task sequencing.

Engagements for Project Controls are often delicate, as they take place in a context of activities already launched with committed stakeholders. Developing project management processes and tools during this phase requires great adaptability, insight, and a sense of perspective.

MIGSO-PCUBED’s involvement was necessary and supported by the company’s Setup & Control as well as Scheduling teams: the WBS was not complete, and some activities could not have been anticipated, thus increasing operational urgency as well as technical, delivery, and certification risks.

After all, scheduling is not just about meeting the client’s expected requirements, although that is the very essence of project management. Scheduling also allows for working in a calm environment, in which quality assurance is provided.

To go further, MIGSO-PCUBED has proposed a “standard sequence” to facilitate and harmonize all schedules (including both internal and supplier schedules) for the “Grand Paris” project, thus strengthening coordination efforts.

This article was originally written in French by Aurélien Chardonneau, Cédric Laurent, and Jonathan Rinfray with contributions from the MIGSO-PCUBED consultant team working for the Société du Grand Paris.

Loved what you just read?

Let's stay in touch.

No spam, only great things to read in our newsletter.

We combine our expertise with a fine knowledge of the industry to deliver high-value project management services.

MIGSO-PCUBED is part of the ALTEN group.

Find us around the world

Australia – Canada – France – Germany – Italy – Mexico – The Netherlands – Portugal – Romania – South East Asia – Spain – Switzerland – United Kingdom – United States

© 2024 MIGSO-PCUBED. All rights reserved | Legal information | Privacy Policy | Cookie Settings | Intranet

Perfect jobs also result from great environments : the team, its culture and energy.

So tell us more about you : who you are, your project, your ambitions,

and let’s find your next step together.

Dear candidates, please note that you will only be contacted via email from the following domain: migso-pcubed.com. Please remain vigilant and ensure that you interact exclusively with our official websites. The MIGSO-PCUBED Team

Choose your language

Our website is not supported on this browser

The browser you are using (Internet Explorer) cannot display our content.

Please come back on a more recent browser to have the best experience possible